Scalable Manufacturing

Flexible Production Services to Bring Your Component to Life

Now that you’ve decided on a material formulation, designed a functional part, and tested the prototype fitness, allow Globe Composite’s established scalable manufacturing services to bring your component to life. Our flexible production operations are setup to produce parts of any size, shape, and quantity at our Stoughton design and technology center. In addition, we also offer assembly, machining, and warehousing capabilities.

As a leading specialists in engineered composites, we have an exceptionally broad range of processing and machining capabilities with a proven track record of success. Globe Composites' facilities include everything from a full-scale machine shop to a prototype model shop, and everything in between.

Our proprietary molding processes allow production to be completely customized to your unique specifications- whether you need one or one million units. Each and every part is produced to be a carbon-copy, with no secondary tooling or finishing required.

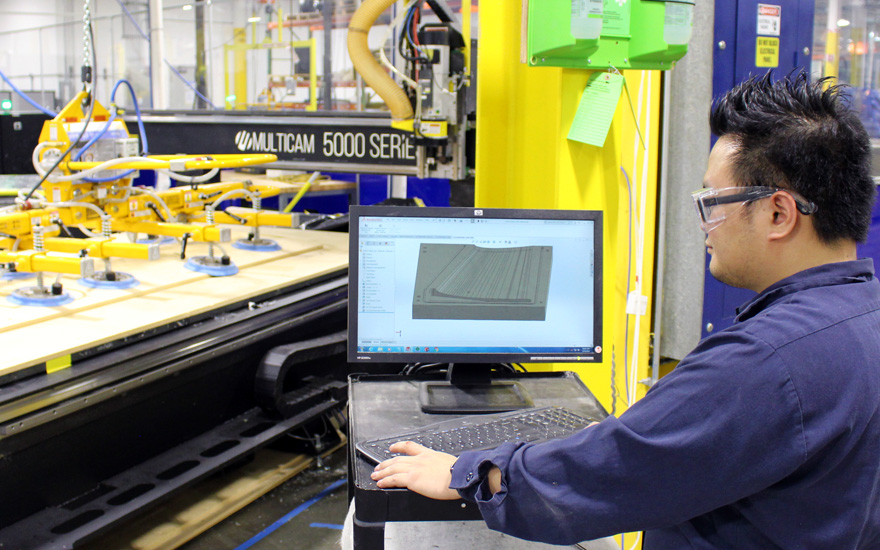

At Globe Composite, we believe that investing in the latest production and composite manufacturing technology is a critical component to successful composite solutions.

Here is a sample of the processing capabilities and machining equipment offered at Globe Composite:

- Seven (7) large-scale CNC milling machines capable of handling parts up to 192” long

- Three (3) CNC Vertical Milling machines, up to a 60 x 30" table, risers up to 29" under quill

- Four (4) Bridgeport and similar milling machines; lathes to 24” swing

- Large capacity Ovens: 10’ x 10’ x 40’ and 8’ x 8’ x 38', both up to 230 °F

- Various smaller ovens to 375 °F

- Two (2) Robotic Surface Finishing Arms

- Robotic Cutting Arm

- Four-stream continuous volume thermoset dispensing machines

- Three-stream thermoset dispensing machines for filled systems

- Conventional synthetic rubber molding, to press capacity of 42” x 42”, 150 tons

- Rubber high pressure injection molding to 8 lbs. per shot, 300 tons

- Thermoplastic and thermoplastic urethane injection molding to 65 cu.in.p/ shot, 300 tons.

- Insert molding and over-molding capabilities.

- Liquid injection molding (silicone) to 3 oz. per shot, 50 tons

- Fiber reinforced laid-up composites to 240”. Filament winding to 21” dia. x 76” long

- 17 heated and pressurized autoclaves, ranging from 8 cubic feet to our largest, which is 20’ long x 5’ diameter and has a volume of 400 cubic feet

- Comprehensive conventional machine shops

- Welding and fabrication of steel and aluminum

- Metal blasting and preparation

- Well-established network of responsive vendors to support special operations such as fabric preforms, mold extrusions, surface treatments, etc.

- Established contract partners: Welding, Tab Steel, Aluminum Coating (epoxy, teflon, powder, etc.)

About Us

Globe is changing the world with composite solutions, and offers a full spectrum of services ranging from the initial material formulation, to the scalable production of your finished component.

Contact Us

For more information, please fill in our online enquiry form or contact our sales offices directly at +1 781-681-6802. From concept to production, we've had over 130 years of experience providing extraordinary solutions to complex problems.