Product Design

Performance Improvement Through Robust Design Processes

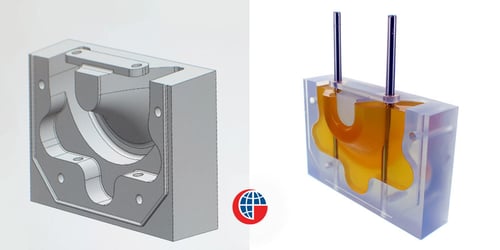

One aspect that truly sets Globe Composite apart from others is our willingness to thoroughly assess our customers' component challenges and then creatively design (or redesign) a part to radically improve performance.

While other companies may provide assistance during the design phase, our staff of research chemists and design engineers tackle your most demanding applications with a collective 200+ years of mechanical design, structural assessment, and automation experience.

We provide our clients full-scale composite design services, including SolidWorks design , Finite Element Analysis (FEA) and full testing services. Globe works with over 300 different types of material which allows us to create lightweight, energy-efficient, and durable parts. In other words, we can replace almost any under-performing part with a composite solution that will last longer, weighs less and therefore be less expensive overall.

From simple wheels to sophisticated conveyor sortation systems, from high-strength gaskets to sonar acoustic panels on submarines, Globe designs products for some of the largest companies across the globe. Using our unique design capabilities, we work with operations, maintenance, product development and program managers to develop specific designs to fit your unique challenges.

About Us

Globe is changing the world with composite solutions, and offers a full spectrum of services ranging from the initial material formulation, to the scalable production of your finished component.

Contact Us

For more information, please fill in our online enquiry form or contact our sales offices directly at +1 781-681-6802. From concept to production, we've had over 130 years of experience providing extraordinary solutions to complex problems.