Commissioned in 2005, the nuclear-powered fast-attack submarine USS Jimmy Carter (SSN-23) is one of the most remarkable vessels ever to sail the seas. This Seawolf-class marvel is no ordinary submarine. It hums with unmatched speed, stealth, and weaponry even compared to more modern boats.  It is also the most expensive SSN submarine the US Navy has ever built, costing over $3.5 billion two decades ago. Like a character in a superhero comic, this is a unique super-sub that underwent classified modifications by the military, producing enhanced physical capabilities that sets it apart from all other submarines.

It is also the most expensive SSN submarine the US Navy has ever built, costing over $3.5 billion two decades ago. Like a character in a superhero comic, this is a unique super-sub that underwent classified modifications by the military, producing enhanced physical capabilities that sets it apart from all other submarines.

Its amazing capabilities has earned its crew the Navy's highest honor: the Presidential Unit Citation for "extraordinary heroism in action against an enemy."

USS Jimmy Carter's Unique Modifications

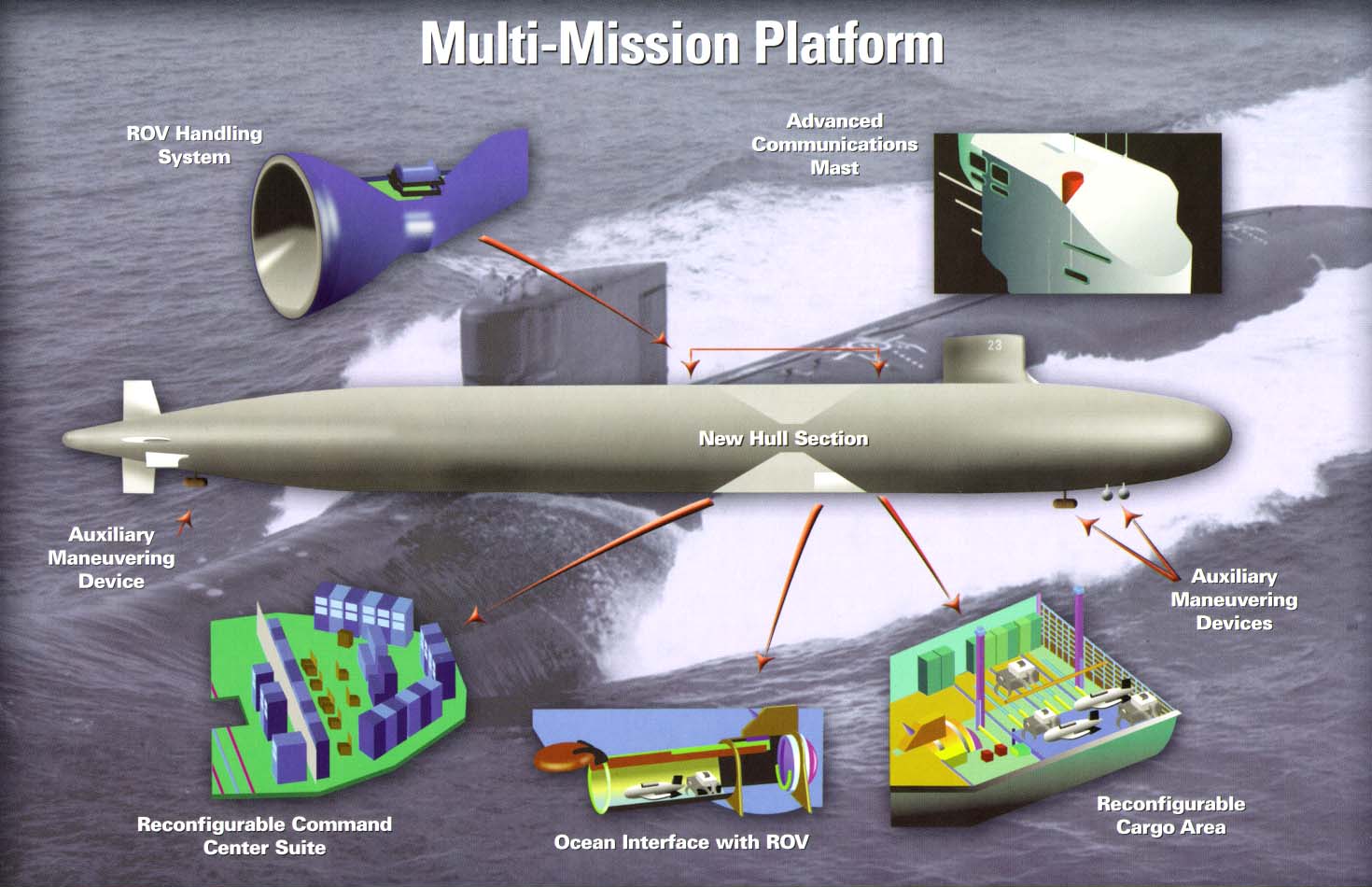

What sets the USS Jimmy Carter apart from other Seawolf-class subs, are the modifications which turned it into a unique Multi-Mission Platform (MMP) submarine. During construction, an additional Ocean Interface (OI) section, sometimes referred to as "the plug," was inserted into its hull, providing extra space for various missions and equipment. The OI section offers a larger payload opening to the sea, and serves as an underwater hangar for a changing variety of roles.

Top view of the insert as it is offloaded at the Groton Shipyard (GDEB)

The OI hull insert reportedly has an “hourglass” configuration, which narrows the interior pressurized hull down to a thinner four-foot-wide passage or "wasp waist" running its length. Normal sub pressure is maintained inside the wasp waist passage. The passage creates a space for crew members to pass through, as well as any operational equipment that must remain in the pressurized area of the sub, such as end-to-end pipes or cables. The space between the wasp waist and the outer hull is the OI hanger area (also called the 'aquarium') , which is filled with seawater and kept at sea pressure. This large MMP area outside the pressure hull, but still within the skin of the ship, is ideal for flexible payloads and naval special warfare (NSW) missions. This internal MMP design keeps a smooth hydrodynamic hull shape that has minimal impact on the ship's draft, while providing a place for any next-generation systems needed in the future.

In addition to the OI section, the SSN-23 also reportedly has “Auxiliary Maneuvering Devices” fitted fore and aft that may allow her to keep station over selected targets in odd currents, as well as an Advanced Communications Mast (ACM).

MPP features reported by General Dynamics Electric Boat (GDEB)

Presidential Unit Citation

The crew of the USS Jimmy Carter received the Presidential Unit Citation in 2012 for what has become known as "Mission-7", with the Navy only saying that it "successfully completed extremely demanding and arduous independent submarine operations of vital importance to the national security of the United States." The SSN-23 was also spotted in 2017 "flying the Jolly Roger", signifying other successful missions.

Cmdr. Brian Elkowitz, second from left, and other officers hold the SSN-23 Presidential Unit Citation pennant (U.S. Navy)

Still on Patrol

Still on Patrol

The USS Jimmy Carter's unique modifications and capabilities underscore the ever-evolving nature of undersea warfare and strategic defense. Our thoughts are with the current crew of the USS Jimmy Carter as it sails towards its 20th year protecting America. It has been reported that a new Modified Virginia class Subsea and Seabed Warfare (Mod VA SSW) sub is planned as a successor to the USS Jimmy Carter. Until then however, the SSN-23 will exemplify its motto of Semper Optima, and remain "Always the Best."

(Note: all information in this post was collected from the public record.)