Globe Composite Solutions prides itself on its responsiveness to customers, its passion to innovate and willingness to prototype new designs and applications. Even before a customer or potential client notices the need for improvement in a certain part, whether old or new, Globe responds with cost-effective and unique design approaches every time. Outlined below is one such case where Globe designers and engineers took a client's critique and turned it into a better, longer lasting part.

Situation

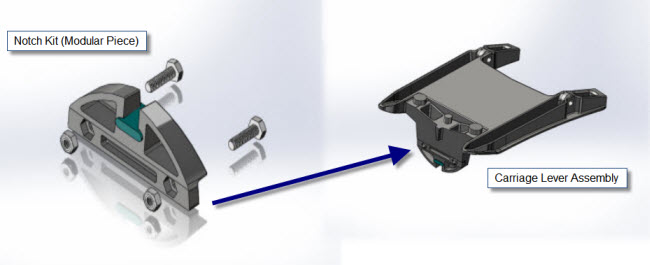

A long-standing package/parcel handling client noticed that a part they routinely purchased from us -- an actuating lever for a tilt-tray sorting system's latching notch -- wore out faster than the rest of the part because of the constant activation of the carriage. Although this notch area was designed to the wear, the entire lever had to be discarded at the end of its useful life expectancy. The client expressed a wish to not have to purchase the entire lever routinely, every time the notch wore out.

Globe's Solution

Globe's expert designers and engineers remodeled the notch area of the carriage lever to now be a modular insert that could be replaced easily, rather than discard the entire component. Now, the entire assembly is even more reliable, durable, and cost effective since the whole lever does not need to be replaced every time.

Benefits & Results

This modular assembly allows for the whole carriage lever to be more durable, reliable, and significantly reduces life cycle costs by eliminating the need to replace the larger lever piece along with the worn out notch. Approximately, the smaller notch kit costs only 10% of the cost of the total carriage lever assembly. This modular approach reduces not only inventory requirements, but also downtime, as customers now can return their sorting system to operation more quickly than before. Overall, the new design highlights Globe Composite Solutions' responsiveness and commitment to excellent client services and innovation.