Last week's newsletter from TradePublications.com included a white paper from Epicor titled, Four Quick Ways to Unlock Hidden Manufacturing Capacity. The paper went on to break down those four ways as:

- Reduce downtime

- Reduce short stops

- Remove product variation

- Establish goals and priorities

Composite parts and components from Globe Composite Solutions helps to achieve all four of these benefits with the one simple step of switching from metal or plastic parts to highly durable, more reliable composite components.

1) Reduce Downtime

One of the best ways to reduce downtime for any manufacturing plant, regardless of industry, is to switch to composite components designed and made by Globe. Composite parts won't bend, snap, or break like metal or plain plastic. Composite parts are engineered to be more durable and retain their shapes better. See how this all-composite grate we designed bounces back into shape after a 600 lb. weight is dropped on it from a 6 feet height. Imagine how well even more complicated parts made with composites can withstand or reform after intense force or shear. Engineered composites, specifically tailored to your business application last longer, hold up better, and rarely fail, significantly reducing downtime.

One of the best ways to reduce downtime for any manufacturing plant, regardless of industry, is to switch to composite components designed and made by Globe. Composite parts won't bend, snap, or break like metal or plain plastic. Composite parts are engineered to be more durable and retain their shapes better. See how this all-composite grate we designed bounces back into shape after a 600 lb. weight is dropped on it from a 6 feet height. Imagine how well even more complicated parts made with composites can withstand or reform after intense force or shear. Engineered composites, specifically tailored to your business application last longer, hold up better, and rarely fail, significantly reducing downtime.

2) Reduce Short Stops

Since many of Globe’s materials can be self-lubricating or friction-free, machinery consistently can run at higher speeds with little or no maintenance like our drive chains or even our pump impellers. For instance, Globe’s Run-Dry® Impellers are made out of a self-lubricating composite that can run dry for up to 15 minutes without stalling or breaking apart. Additionally, imperfections or irregularities on the surfaces of parts can be eliminated, leaving very little to nothing that can get caught in the machinery's operations. This almost seamless design of components means a definite reduction in short stops or hiccups in a system.

3) Remove Product Variations

Since Globe's composite components are made via repeatable production processes like injection or liquid-cast molding, there's little to no variation between parts, yielding consistent, high quality parts. Also, Globe designs parts to minimize secondary machining, further reducing the possibility of inconsistent part quality. In essence, parts are formed like clones -- the same part again and again from the same mold with almost zero variation.

Since Globe's composite components are made via repeatable production processes like injection or liquid-cast molding, there's little to no variation between parts, yielding consistent, high quality parts. Also, Globe designs parts to minimize secondary machining, further reducing the possibility of inconsistent part quality. In essence, parts are formed like clones -- the same part again and again from the same mold with almost zero variation.

4) Establish Goals & Priorities

What are your goals for a part redesign or supplier change?

- Improve reliability?

- Save money?

- Reduce energy consumption?

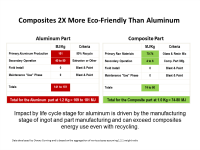

Globe can help you achieve all of these and other goals. Not only are composite components more durable and reliable, but also they're more energy efficient and eco-friendly. How? It's simple:

- First, it takes half as much energy to form and shape a composite component compared to aluminum or steel.

- Secondly, since the parts last longer and breakdown less, there're less parts being thrown away.

- Lastly, composite components are lighter – consuming less energy to operate a system using composites.

Globe Composite Solutions is well known throughout the composites' industry as a forward-thinking firm with an uncommon willingness to speculatively prototype projects. Let our team of experienced and highly skilled engineers, machinists, chemists and molders help you determine the best way for Globe components to save you time, money, and energy.

We offer a full range of design, mold fabrication, prototyping and production services; fill out the contact form to submit a project to us today.