Like invisible aliens crawling over craggy terrain, microbes are everywhere indeed. As such, a plethora of antimicrobial and antibacterial advanced materials have hit the market. Globe Composite has the perfect solution. Globe has developed a family of high-strength, injection-molded, reinforced thermoplastic materials, Brandonite® 9012, for medical and food service use.

Like invisible aliens crawling over craggy terrain, microbes are everywhere indeed. As such, a plethora of antimicrobial and antibacterial advanced materials have hit the market. Globe Composite has the perfect solution. Globe has developed a family of high-strength, injection-molded, reinforced thermoplastic materials, Brandonite® 9012, for medical and food service use.

What is Brandonite® 9012 Antimicrobial Material?

![]() Brandonite® 9012 is a series of advanced materials infused with a unique nanosilver substance, since nanosilver is naturally and inherently antibacterial. You can even buy vials of colloidal silver at Whole Foods. A drop is great for a sore throat.

Brandonite® 9012 is a series of advanced materials infused with a unique nanosilver substance, since nanosilver is naturally and inherently antibacterial. You can even buy vials of colloidal silver at Whole Foods. A drop is great for a sore throat.

The Brandonite® composite base polymer is impregnated with nanosilver, and then compounded with FDA-approved fibers, without degrading the structural performance of the end-product. The infused silver remains suspended throughout the entirety of the composite material, slowly extracting over a period of time via the surface of the material. This process makes the composite not only immensely strong and durable, but also anti-microbial inherently.

What can I do with Brandonite® 9012?

What can I do with Brandonite® 9012?

Brandonite® 9012 was first developed for use in the food preparation industry. The built-in anti-microbial agent helps food preparation and transport by warding off any pathogen-causing fungi, mold, yeasts, mildew, algae and other microbes in gears, housings, mixers or other parts that are difficult to clean.

Although initially developed for the food preparation industry, Brandonite® 9012 comes in two different 'flavors' (pun intended) and can be adapted to the healthcare and medical device industry easily. Globe offers Brandonite 9012-AS which provides antimicrobial protection for 2-5 years and the longer lasting Brandonite 9012-LS which lasts up to 10 years. Either of these formulas could be adapted for the medical industry. For example, thermometer or scope covers would benefit a great deal if made from Globe's Brandonite® 9012 -- or any other medical device that comes in contact repeatedly with a patient or with multiple patients.

Although initially developed for the food preparation industry, Brandonite® 9012 comes in two different 'flavors' (pun intended) and can be adapted to the healthcare and medical device industry easily. Globe offers Brandonite 9012-AS which provides antimicrobial protection for 2-5 years and the longer lasting Brandonite 9012-LS which lasts up to 10 years. Either of these formulas could be adapted for the medical industry. For example, thermometer or scope covers would benefit a great deal if made from Globe's Brandonite® 9012 -- or any other medical device that comes in contact repeatedly with a patient or with multiple patients.

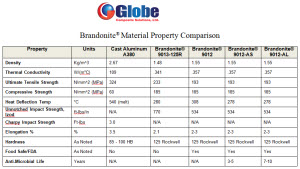

Is Brandonite® 9012 expensive? Why not use stainless steel or coated aluminum?

Both good questions… In fact, Brandonite 9012 is far more cost effective than stainless steel or even coated aluminum when you factor in secondary machining and coating processes. Stainless steel is just more expensive regardless of how you look at it. Furthermore, Brandonite is about 70% lighter than stainless steel and 30% lighter than aluminum making it easier to service machinery or less expensive to ship components. And, the coating on aluminum components can be scratched or chipped, thereby compromising its anti-bacterial or food-safe protection.

Both good questions… In fact, Brandonite 9012 is far more cost effective than stainless steel or even coated aluminum when you factor in secondary machining and coating processes. Stainless steel is just more expensive regardless of how you look at it. Furthermore, Brandonite is about 70% lighter than stainless steel and 30% lighter than aluminum making it easier to service machinery or less expensive to ship components. And, the coating on aluminum components can be scratched or chipped, thereby compromising its anti-bacterial or food-safe protection.

Lastly, since the Brandonite® parts are generally molded as one single piece, there's no painting, welding, bending, tapping or other secondary operations needed after molding. It will keep its color and aesthetic appearance throughout the life of the part and resists scratches and normal wear and tear as well.

Large or small quantities, small or large sizes. Globe handles it all.

Brandonite® parts can be formed into almost any size, from as small as your fingernail up to 10 feet in length and from less than 5 grams to 10,000 grams. Due to our unique molding processes, Globe can cost-effectively mold small quantities of parts-- even as low as 2,000-2,500 parts.

Submit a project to us today to see what Globe can make for you from our anitmicrobial Brandonite®.