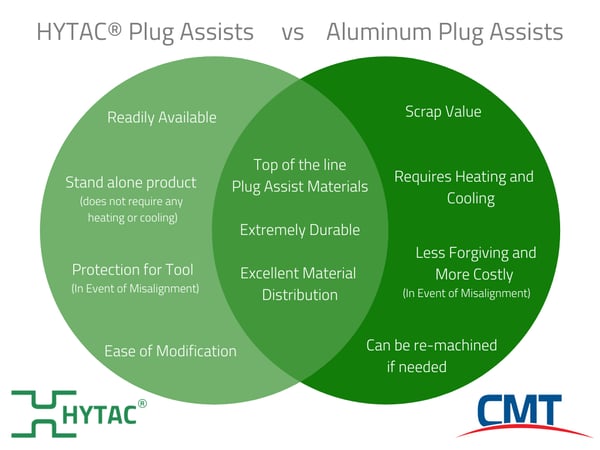

There are many options available to thermoformers when it comes to plug assist materials. Wood, Nylon, tooling board, Syntactic Foam and Aluminum are among the most popular. The top-of-the-line options being Syntactic Foam and Aluminum. Though they are both excellent products, each has its pros and cons. Understanding these characteristics can help you make sure you are using the best product for your thermoforming process.

We recently surveyed Thermoformers on our Twitter and LinkedIn accounts, asking “What is the most important feature you look for in your plug assists?” Plug surface finish came in first place with 73% of the votes. So, when we compare HYTAC® Syntactic Foam with Aluminum, which has the better surface finish?

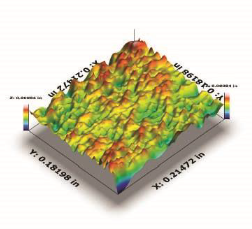

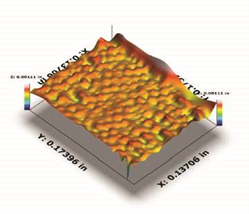

With syntactic foam, the microscopic surface roughness of our material contains peaks and valleys that create an air barrier between the plug assist surface and the sheet surface. This helps create less plastic distortion from the plug assist touching the sheet material. Syntactic can be easily modified by sanding, grinding, and polishing the plug assist surface allowing you to modify sheet distribution. In comparison, aluminum plug assists need to be machined to their finished surface. These plugs can be super smooth which can create surface tension during the thermoforming process, causing the sheet to rip instead of flowing down into the mold cavity. If you tried to sand an aluminum plug surface, you would only create scratching that would cause mark off on your finished product. A polished plug with microscopic peaks and valleys is the ideal plug assist surface finish.

| Syntactic Foam Surface of a Machined HYTAC-FLX Plug Assist |

Syntactic Foam Surface of a Polished HYTAC-FLX Plug Assist |

|

|

The 2nd place answer for most important feature in your plug assists was durability. Aluminum is an extremely durable product and will last for millions of parts, but this durability has its disadvantages as well. If there is any sheet interference with the mold (a double sheet, cold sheet, chilled sheet, misalignment or just bunged up material) an aluminum plug assist will continue to perform, likely damaging your mold in the process. HYTAC® syntactic foam plug assists are more forgiving and capable of protecting an expensive mold in the event of a misalignment. Our thermoplastic line (HYTAC®-B1X and HYTAC®-XTL) are comparable to aluminum in durability but have the added benefits of ease of modification, syntactic surface finish and more protection for the tool in the event of a mishap or failure.

How about performance? Between HYTAC® syntactic foam and Aluminum, which will provide the most reliable performance when it comes to producing millions of parts? HYTAC® syntactic is a stand-alone product with superior Thermal Conductivity (TC) characteristics. It does not require heating or cooling of the plug. Aluminum starts chilled and requires heating/cooling lines to keep it at the optimal temperature throughout the thermoforming process. 90% of the time, the plugs are above the sheet during the thermoforming process. Due to the violent nature of the thermoforming process, leaks can occur from the heating/cooling lines. These leaks can cause blemishes on the plastics. Aluminum will also expand up to 1% of it’s size when heated whereas syntactic foam has a very low Coefficient of Thermal Expansion (CTE), greatly minimizing the standard deviation between parts.

Another factor to consider when comparing these two materials is the amount of waste associated with heating/cooling. Starting up using aluminum plugs requires preheating through a water system or running the plugs through the warmed sheet. In doing so, you can waste material trying to get your parts to the correct distribution and clarity. With syntactic, once your sheet material is warmed up you can start immediately, saving material and money.

Aluminum does have one important characteristic that syntactic does not and that is scrap value. Though aluminum is typically more expensive, you can scrap the metal when you no longer need the plug assist and get money back. Lastly, lets compare availability. In this economy aluminum can be scarce and have long lead times. HYTAC® syntactic foam is built every day with product typically on the shelf and ready to ship same day.

SHARE